Summary

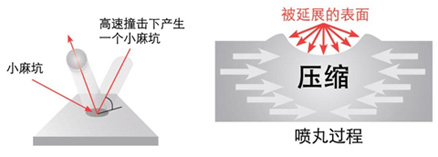

Shot blasting category: there are three types according to shot blasting application. 1. shot blasting cleaning 2. shot peening 3. shot peening forming shot peening is traditional surface treatment technology, the principle is : by means of impacting of high speed shots on the workpiece, to make it plastic deform in order to produce residue stress, and increase the bent/twist fatigue strength of parts, improve stress corrosion splitting performance.

The shot peening is a process of cooling, that is numerous round shots beating on the surface, like a micro hammer beating on the surface to produce small indentation and hollow.

You can imagine, in a pressure stress area, split is hard to form or extend. As almost all the fatigue and stress corrosion occur on the surface or near the surface, thus by shot peening, the lifetime of spare parts can be extended. The residual stress by shot peening must reach half of the tensile strength of part material.

The notable enemy of metal fatigue failure is tensile stress. The production of tensile stress is due to alternate load by exterior or residual stress of production process like welding, grinding. Tensile stress tries to stretch or pull the surface to cause split in the final.

Application

Aviation industry

Aviation industry has high requirement for the spare parts, it requires not only light, but also it can be loaded in extreme bad environment. By virtue of protecting the surface of parts from exterior destroy and extend lifetime, we can improve the total performance of spare parts.

Most parts used in aviation, including airplane frame, wings, motors, landing gear, driving device, or transmission parts (gear), all adopt shot blasting technology to meet the performance index of its material. |

|

|

Automobile industry

The requirement of automobile industry is low cost, and keep good performance under high alternate load. By virtue of protecting surface from damage of circulation load when operating, the surface treatment can improve the performance of parts. The most metal material used in automobile industry all adopt shot blasting treatment technology to meet its performance requirement of material. |

Locomotives

It has high requirement on the hardness, abrasive proof and anti fatigue of the material. By virtue of protecting surface from damage of circulation load when operating, the surface treatment can improve the performance of parts.

The most metal material used in locomotive industry all adopt shot blasting treatment technology to meet its performance requirement of material. |

|

|

Electric energy industry

In the electric energy industry, the shot blasting technology can increase the performance of steam, gas turbine, like the rotary table, blade, assistant spare parts and equipment, at the same time reduce the fatigue invalid like erosion, micro abrasion, fatigue and stress corrosion. For transmission elements, gear and axis, shot blasting technology is used widely to prevent invalidity of spare parts. But recently, shot blasting is used to increase bearing capacity of key structure. |

Other fields

The shot blasting is used in engineering machinery, mining, petroleum chemical, natural gas, city heating and gas supply, medical equipment, sea engineering, large and special ship, power equipment, energy saving environment protection. |

Shot peening elements

Shot peening elements are: 1. shot peening equipment and attachment. 2. media: all types of shots 3. process: shot peening parameter, relationship with fatigue strength.

1. shot peening equipment:

(1)pneumatic shot blaster is applicable to many kinds of spare parts, with low output and complicated shape

(2) mechanical centrifuge shot blaster is applicable to few kinds of spare parts, with big output and simple shape.

2. shot blasting media: steel shots, iron shots, stainless steel shots, wire shots, glass bead, ceramic shots, nickel-base alloy shots, etc.

Shot requirement:

1.the shots should be ball shape, without any sharp angels, besides, in order to prevent break in the impacting process, the shot should have certain hardness.

2.the required shots for circulation should be above 80% in total shots.

Shot selection principle

1. Ferrous metal parts can be any kind of shots.

2. Nonferrous metal and stainless steel parts are recommended to use glass bead or stainless steel shots. If iron casting, steel casting shots are used, it should be cleaned after shot blasting to prevent chemical corrosion.

3. For large parts that has strict requirements of surface luminosity, big shots can be used to have higher shot blasting strength; For parts that has higher requirements of surface luminosity, small shots can be used.

3.Shot peening parameters

.jpg)

Impact of the shot peening process parameters: projectile materials, projectile size, hardness projectiles, projectile velocity, projectile flow, spray angle, injection time, centrifugal wheel distance to the part surface.

Strength control

Shot peening strength represents the energy that shots beat produces, it is an important parameter in the shot penning process, a key factor to insure the penning production can be repeated, the energy that shots eject on the surface is directly related to the pressure stress. Using bigger shots and/or increase the shot speed can increase the strength of shots. Besides, the angle and material will affect the strength.

Coverage rate

In order to obtain high quality strengthening result, it must insure that it meets coverage rate that peening requires. The coverage rate is to measure the covering area of small dents forms by the shots beating. The coverage rate is not allowed to below 98%, if it can not reach 100%, the stress corrosion and fatigue split will occur and spread on the places where is not blasted, result in the split and invalid of parts. If required coverage rate does not exceed 100% (like 150%, 200%), then the time is required to be increased as ratio.