Medical implant strengthening designed custom-made digital control shot blasting solution, increases strength and persistence of medical implant,; for precise and repetitive process, automatic shot peening equipment is used. Except for the precise control of shot blasting/peening technology, Liangshi develops and provides complicated material treatment process of automatic operation, meanwhile manufactures components of clamping device and mask.

Treatment solution that meets surgery standard: wet spray technology solution can reduce ash and other pollution, so is very welcome in medical apparatus.

|

Medical apparatus digital control automatic shot blasting equipment

Liangshi designs a set of digital control automatic shot blasting equipment of medical apparatus for a Japan-invested company. The electric control is PLC integrated control, workpiece loader system is servo system controlled.

The automatic shot blaster can meet each requirement of shot blasting process specified for medical apparatus.

|

|

Obtain hierarchical porous of titanium surface nanostructure composite technology and its formation mechanism.

(1 Materials Science and Engineering, Shanghai Jiaotong University, Advanced Materials Research Center, Shanghai 200240; 2 Shanghai Ninth People's Hospital of Oral and Maxillofacial Surgery, Shanghai 200011; .. 3 Shanghai Liangshi Blasting and Coating Equipment Co., ltd. Shanghai 201413)

Since the 1870s, pure titanium "osseointegration" phenomenon have been proposed by Branemark and Schroeder, titanium draw more and more attention in biomedical research and applications as implants. Has the highest ratio of strength and weight among all structural metals, the high stability of the exhibition in corrosive environments, as well as its non-magnetic and non-toxic characteristics that make titanium implants have a distinct advantage.However, the biological activity of titanium implants low. In clinical application, the "osseointegration" has a long cycle.

In order to improve the biological activity of titanium surface, people take several of modification of the surface of titanium. Mainly in two ways: (1) change the surface morphology and structure; (2) optimize the surface chemical composition. In recent years, domestic and foreign researchers reported that the binding capacity of titanium and bone can be increased by blasting, acid, alkali treatment, anodizing, micro-arc oxidation and various depositing techniques and other methods. Studies have shown that after the surface-modified titanium can form hierarchical porous anatase crystal morphology and roughness of a certain phase, which has a better biological activity.Young found that the bioactive of porous anatase or rutile prepared by anodic oxidation is Conducive to the growth of apatite. Hierarchical structure of porous titanium surface topography is conducive to osteoblast differentiation variation, but the proliferation of osteoblasts compared to smooth titanium surface is greatly reduced. Study reported that by changing the chemical composition of the surface of titanium can improve osteoblast proliferation,Tsukimura found titania surface layer of titanium accelerated the proliferation of cells.

|

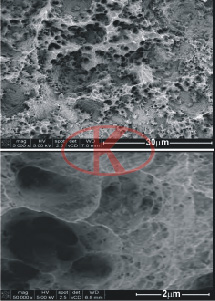

Surface SEM image of SLA sample after the shot blast acid etching

|

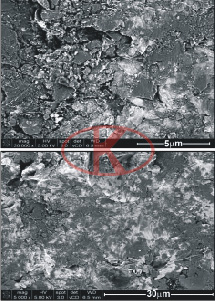

Surface SEM image of ∮150μm glass bead 40S blasting treatment

|

Pure titanium surface modified compound technique is brought forward innovatively based on shot blast—acid etching-anodic oxidation. Conclusion as follows:

(1) SLA sample after the shot blast acid etching is composed of 2-3μm micron structure and small amount of 100~400nm nano-pores. AO samples after the anodic oxidation treatment has only 20~400nm nano-pore structure, SLA+AO samples after compound process of sandblast acid etching and anodic oxidation increase large amount of nano-pores of 20~200nm.

(2)AO and SLA+AO samples have surface oxygen enrichment and Anatase crystalline phase.

SLA+AO samples after compound process of sandblast acid etching and anodic oxidation have multi-hole structure, surface oxygen enrichment and Anatase crystalline phase, which is more suitable for surface modification of mouth titanium implant.

|