In the electric industry, the shot blasting technique can improve the performance of steam, fuel gas turbine, like the rotary table, blade, spare parts and equipment, meanwhile can decrease erosion, abrasion fatigue and stress split.

On the aspect of transmission element, gear and axis, shot peening technique is used to prevent the invalid of spare parts, but recently, shot peening is used more and more in increasing the carrying capacity of key structure, like the supercritical power plant pipe minor-caliber steel tube inner wall shot peening; overload bench test of screw drive and driven bevel gear of automobile is also testified.

|

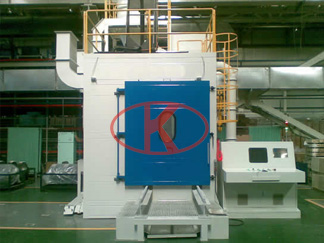

Wind power booster gear shot peening machine tool

|

|

Wind power bearing control automatic shot peening equipment

|

|

As the wind power turbine is getting larger and larger, the gear box is more and more complicated. Due to gear invalidity the equipment stop loss is becoming expensive. After the wind power turbine is installed, it is under the action of estimated high carrying load stress, at this time, the high contact stress of booster gear and bearing surface will cause crack, hollow, scratch, and other non-recoverable abrasion.

Wind power electric generator has high requirement for gear box: small volume, light weight, high reliability, long life, easy to maintain. What ever gear is used, the gear will need hardening and strengthening treatment to suit special environment requirement like the wind farm, especially to reduce the noise of wind fan when it is rotating. The hardening function is to increase the gear hardness, but it will misplace and deform the gear material, so it has to be shot peening thereupon.

|

|

Shanghai Liangshi designs and manufactures wind power and ship machinery equipment bearing control automatic shot peening equipment for a famous bearing company in Dalian, in the wind and ship industry corrosion proof requirement of bearing is high, the surface treatment precision is high, and the workpiece diameter is large, so Liangshi develops automatic rotary mechanism and 3-axis manipulator automatic shot peening equipment, the workpiece automatic rotary mechanism adopts imported motor driving rotary worktable to rotate, the rotary speed is frequency adjustable, the workpiece rotate stable. As machined surface of turntable bearing is many and complicated, 3-axis manipulator is adopted, the X-axis shift precision is no more than ±1mm, it can fully satisfy the automatic shot peening requirement, Z-axis is similar with X-axis, configuring linear bearing to make it more accurate and stable, realize digital control; A-axis can work when 2-4 guns spray guns are swaying at the same time between 95~+95

|

Wind power fan blade shot peening machine tool

The fan turbine is under vibrating stress of wind power in a long time, especially under turbulent wind field environment. The rotary blade is forced to vibrate under this periodical external force action, and sometimes this vibrating is sudden, resonance in a short time leads to appearance of split, the vibrating stress is large and destructive force is strong, thereby split and even break is produced. Besides, as the vibration of blade and neighboring blade is mutual interfered and destructive force will cause the split and break on the blade surface. In the operating process of motor, such as high speed object impacting on the blade, it will easy to cause split. So when designing the motor blade, wind strength, drive model, metal anti-fatigue feature of rotary blade need to be fully considered.

At present, the most economic and effective way to solve the motor blade metal fatigue is shot peening. By bringing in a residual press stress on the surface of blade surface, it can offset or overcome the destructive tensile stress to improve anti-fatigue strength of blade.

0

minor-caliber stainless steel tube inner wall shot peening equipment

Along with the development of supercritical power plant and related industries, the inner wall oxidation resistance requirement of stainless pipe like the stream pipe is increasing continuously, so the manufacturing process of equipment is required to be more advanced. Many years of research by expertise at home and abroad shows that, inner wall of stainless steel pipe can be improved of its oxidation resistance by shot peening, the experiment shows that the inner wall micro structure of stainless steel can be changed by shot peening, in the process of using, all kinds of elements ( especially Cr) will change to improve oxidation resistance greatly. The thickness of oxide layer will 0.07%~1.7% of which is not shot peened, and the oxide layer will not fall off. At present the stainless steel pipe manufacturers in domestic all require to use the shot peening equipment to improve the oxidation resistance of inner wall, at the same time make the wall hardened.