|

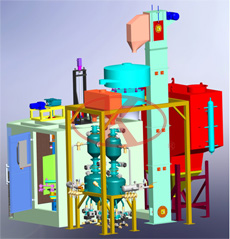

Shot blast strengthening equipment

The shot blast strengthening device mainly consists of the following parts: high wear resistant shot blasting booth, shot blaster system, work piece conveying device and spray gun automatic feeding device, shot recycling mechanism and multi-class separating system, dedusting equipment, electrical control system.

Accessory equipment consists of compressed air processing system, pressure control system, automatic supplement shot system, shot flow controlling system, automatic or semi-automatic feeding device, work piece positioning installation clamp, shot blasting strength, coverage inspection device.

Workpiece conveying device: vertical, level, rotary

Spray gun automatic feeding device: single-axis, multi-axis, mechanical arms

Electrical control: CNC system control

|

|